METALLURGY

Metals at Alalakh – The Crazy World of LBA Small-Scale Metallurgy

The metallurgical footprint of LBA Tell Atchana/Alalakh, presented in Johnson (2020), was in no way what had been expected. As a LBA urban center, we had expected to see a relatively standard set of production practices associated with secondary metallurgy. That is, maybe some refining of metal, melting, casting, and the production of finished objects. In terms of material, since we were focused on the Area 4 workshop outside the palace, we expected to see mostly copper and possibly some bronze. For the few palace contexts we examined, we expected bronze and had essentially no expectations of precious metals since they are usually easily identified and we had not seen nor sampled such materials. Finally, we expected to see largely the same raw material sources across the entire site as explored through lead isotope analysis. While copper and bronze certainly predominated in the assemblage, many of our other assumptions were wrong.

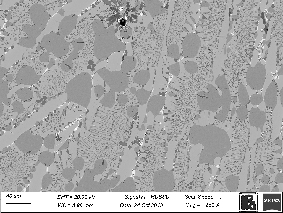

Area 4 yielded what has proven to be among the most complex assemblages of metallurgical remains seen in a Late Bronze Age urban context to-date. Though we certainly found our evidence for secondary metalworking in the form of molds, casting spill, crucible slags, and finished objects, that was only part of the picture. We also identified copper smelting slag, multiple examples of a tin-bearing iron arsenide compound known as speiss, as well as mineral inclusions embedded in workshop floor samples that demonstrated ore beneficiation and smelting within different parts of the Area 4 compound. In short, the entire metallurgical chain of production was in evidence in this small area. More surprising, however, was that closer microscopic examination of the speiss samples and comparison of their elemental composition with the trace element composition of some bronzes showed that this material was involved in the production of tin bronzes via both co-smelting and direct addition of a master alloy of 66% Cu-33 % Sn – examples of which were also excavated in Area 4.

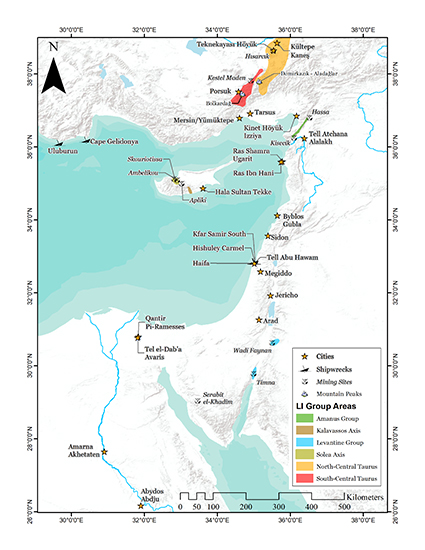

Much of the palace assemblage did turn out as we had expected, yielding primarily secondary production contexts with somewhat larger quantities of bronze. We did have the unusual experience of identifying a unique Cu-Ag-Ni alloy, which appears to be unattested elsewhere thus far. What was truly interesting here, however, was that lead isotope results showed that the palace metalworkers and those in Area 4 sourced their metals largely from two different networks, with relatively limited overlap. Much of the metal seen in the palace showed lead isotope patterns suggestive of mixed metals, metals coming from the northern parts of the Central Taurus, and metals coming from Cyprus. This is noteworthy because it largely agrees with what we know of textual accounts of the metals trade in the LBA Mediterranean. Where things begin to diverge is when we consider Area 4, where most of the metals – including all the speiss samples – originate from the southern portion of the Central Taurus, and particularly from an area called Bolkardağ.

When studying metals in the ancient world, because we focus heavily on textual evidence for supporting details, we tend to assume that palaces, as the dominant economic entities of the time, controlled most of the flow of metals owing to their status as a valuable commodity characterized as requiring large capital inputs and labor organization to produce. The Alalakh evidence adds nuance to this image, instead supporting an argument for two separate metal economies operating in parallel – one for those occupying the palaces, and one for everyone else. While more research is needed in the highlands of the Taurus and Amanus Mountains to help illuminate how these networks functioned, historical evidence from the region and ethnographic evidence from other highland areas of the world strongly supports the existence of this type of model.

Johnson, M.A., 2020. Crafting Culture at Alalakh: Tell Atchana and the Political Economy of Metallurgy (Doctoral Thesis). The University of Chicago, Chicago, IL.